Esperanto

Esperanto

Shqiptare

Shqiptare

Euskara

Euskara

Zulu

Zulu

Latinus

Latinus

Cymraeg

Cymraeg

தமிழ்

தமிழ்

Slovak

Slovak

Slovak

Slovak

Afrikaans

Afrikaans

Quality Management

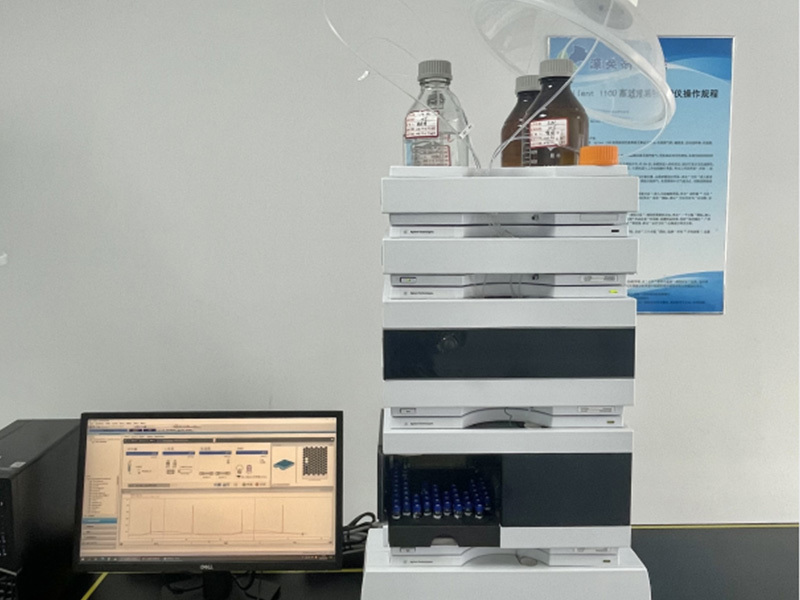

Quality Testing Organizations and Equipment

At Shanher Lithium, each R&D center and production base is fully equipped with advanced quality supervision, management, and testing organizations. The quality management personnel across various departments hold at least a college degree in chemical engineering or chemical analysis, with more than 40 employees dedicated to quality management roles. Additionally, we collaborate with numerous universities and testing organizations, with over 5 experts providing quality management consultancy services.

To enhance quality management, we have outfitted each department with high-standard testing and laboratory equipment. This includes 5 Gas Chromatographs (GC), 10 High-Performance Liquid Chromatographs (HPLC), 15 drying testing devices, 8 moisture testing devices, 4 water quality testing devices, 1 Plasma Emission Spectrometer, and various other pH testing, electronic balance, and physical-chemical testing equipment. All testing devices, sourced from renowned international brands like Shimadzu, Agilent, and Mettler-Toledo, are capable of conducting comprehensive tests on research projects and production base materials, covering moisture, purity, content, COD, ammonia nitrogen, and other parameters. This facilitates R&D process monitoring, testing, and analysis by the research team and meets the quality testing and control needs of intermediates and products at the production base.

Quality System Architecture

The quality system architecture, designed in line with GMP requirements, includes the CEO, our quality management platform, and the quality management departments at each production base.

The CEO is the highest decision-maker for quality-related matters at Shanher Lithium.

Our quality platform, functioning as an independent segment of management, is responsible for overseeing all quality-related management duties within our company.

Each production base is equipped with an autonomous quality management department, functioning independently of the production system, and is responsible for all quality management duties within that base.

Quality Management System

Quality management activities: The primary quality management activities in daily operations are based on the PDCA (Plan-Do-Check-Act) cycle. Utilizing PDCA as the foundation, daily quality management involves planning tasks, implementing plans, evaluating the effectiveness of implementations, integrating successful outcomes into standards, and addressing any unsuccessful elements in the next cycle for continual improvement.

Quality documentation system: Our documentation system is categorized into company-level and factory-level documents. All production bases of our company undergo certification for three systems, with each production base’s documentation structure established in accordance with ISO 9001 standards and company-specific requirements.

At each production base, the principal quality management processes are methodically organized and established across six key areas: quality assurance (QA), quality control (QC), materials, production, equipment and facilities, and label management.